When it comes to choosing hardwood floors, not only can you choose between solid and engineered hardwood, but there's also pre-finished and site finished options. Which is better? Well, each has its benefits.

Let's explore these hardwood flooring finish options in more detail.

SITE FINISHED VS. PRE-FINISHED HARDWOOD

What is Site Finished Hardwood?

When you opt for site finished hardwood, you are purchasing wood flooring that will be shipped to your home unfinished to be sanded, possibly stained and then sealed and finished with a protective layer on the job site in your home.

The process takes time, can be messy from the sanding - although dustless refinishing is available - yet enables you to customize many aspects of the installation such as:

- The choice of finish – water base polyurethane, oil base polyurethane, or natural oil finish (more detail on these choices below)

- Sheen level – high gloss, semi-gloss, matte

- Stain colors

- Custom installation patterns such as herringbone, borders, inlays and medallions

- Trying to match exactly an existing wood floor

- Future refinishing

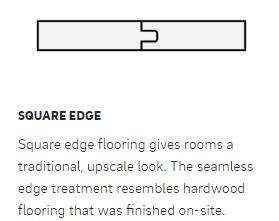

In addition, on-site finishing allows you design options such as non-beveled edge profiles.

Traditionally, you choose on-site finishing for a new construction project when

Remember that, during this time, you can't walk on the floors or put furniture on them and the smell of the finishing products may be unpleasant.

Site Finished Choices

Here's more detail on the different floor finishing methods you have available with site finished hardwood floors:

- Oil-based polyurethane can have an offensive odor. It is expensive and the finish will amber over time. You'll need to have multiple coats applied and the floor needs 3-5 days to dry before it can be walked on.

- Water based polyurethane has less odor and costs slightly more than oil-based. The finish will remain clear over time. Although it requires multiple coats, it dries faster and can be walked on between coats (so it can be applied in the morning and walked on in the evening). Furthermore, a commercial hardener can be used to make it more durable for an extra 50 cents a square foot.

- Oil finish emits no VOCs which means no chemical smells. Of the three options, it costs the most. However, the finish stays consistent over time, it requires only one coat, it can be walked on after 36 hours, and it's the easiest to repair.

Another Site Finished Myth

One of the myths of unfinished hardwood is that the entire floor gets coated with one smooth coating of finish leaving no spaces between the boards. In a perfect world that would be true, however, wood is a natural living product and will expand and contract during the different seasons.

For example, here in the Northeast during our humid summers, hardwood floor will absorb moisture from the humidity and the boards will swell. In the winter when it gets cold and dry the boards lose that excess moisture and contract. Once this expansion and contraction occur that smooth finish is no longer a smooth coat.

You can minimize the expansion and contraction by using a humidifier in the cold months and a dehumidifier in the hot months. Ideally you want to keep your home between 30% - 50% relative humidity and between 68 degrees and 72 degrees. Thankfully these are conditions humans feel comfortable as well.

What Is Pre-Finished Hardwood?

Pre-finished hardwood flooring has grown considerably over the last fifteen years as hardwood manufacturing has become more technical and delivers more style, design and performance options. As you might imagine, in the case of prefinished hardwood flooring, the finish is part of the flooring manufacturing process and the product ships to your home ready for installation.

What that means is that:

- The floorboards are particularly durable a result of the aluminum oxide finish and the newly introduced Diamond 10 finish from Armstrong.

- Installation is faster and easier, furniture can be placed on the floor immediately after the installation.

At the same time, you may not have as many color and finish options but you can add borders and medallions to completely customize the result.

Pre-Finished Flooring Means Durable Flooring

When the flooring manufacturer finishes wood, it uses commercial processes in a controlled environment to apply powerful chemical sealers such as aluminum, titanium or other oxides embedded in a UV-cured urethane coat which adds the equivalent of the second hardest surface known to man (i.e., diamond) to the finish.

The end result is harder than anything applied on-site. The finish lasts considerably longer and carries a better warranty for the homeowner (e.g., 5 to 25 years vs. 3 to 5 years for site-applied finishes).

Easier Installation with Pre-Finished Flooring

Above you read how involved on-site finished flooring installation is. That's not the case with pre-finished flooring which requires no sanding and staining. Instead, once installed, you can immediately walk, set up furniture and start living on your floors, and with lots less mess.

Easier Floor Maintenance

The durable finish on pre-finished flooring means that it's often easier to maintain your floors as they'll be better able to withstand stains, scratches and the general abuse of daily living. Although refinishing your floors will be more involved (i.e., heavy sanding to remove that intensely hard finish), you won't need to do so for a long time.

To make repairs, you'll need to either replace the problem section or refinish the entire floor.

What's Different about Pre-Finished Hardwood Flooring?

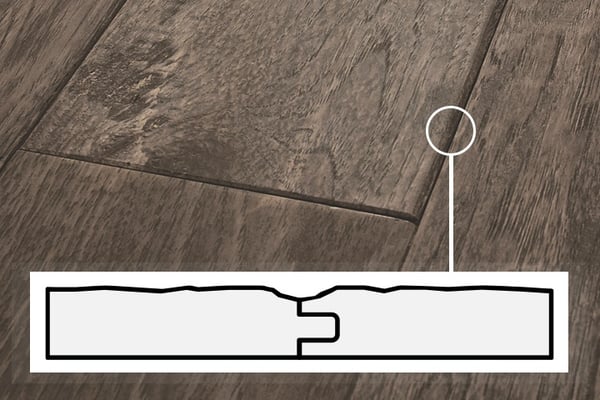

Perhaps one of the biggest differences between pre-finished and site finished hardwood flooring has to do with plank beveling. Often, pre-finished planks have beveled edges unlike site finished which are square and make edges less visible.

You also don't have sealed plank seams which means that some dirt can get caught.

What About Subfloor Preparation?

Subfloor preparation is something we consider important to bring up before any kind of flooring installation whether site finished or pre-finished. Flaws and issues need to be addressed before installation.

- For height irregularities, sanding during the site finishing can be enough.

- In the case of pre-finished, you need to ensure that your subfloor is perfectly flat since you don't have the option to sand on site.

PRE-FINISHED VS. SITE FINISHED HARDWOOD: WHICH IS BETTER?

The choice of pre-finished vs. site finished has more to do with your own preferences and goals than whether one is truly better than the other. One provides you with a wealth of customization options whereas the other offers quicker and easier installation.

At the same time, because pre-finished hardwood products are manufactured in a controlled environment, less can go wrong. For example, you won't find foreign particles, hair, dust

Finally, the prefinished hardwood manufacturers offer a warranty on the finish that carries value for the consumer.

WHICH HARDWOOD FINISH DO YOU THINK IS BEST FOR YOUR HOME?

What is your reaction to this article? Which finish seems better for your home? Does the article answer all your questions? If not, let me know in the comments or contact us.

When you visit one of our showroom location in Carrollton, you'll be able to discuss both types of finish in greater detail.